details and description

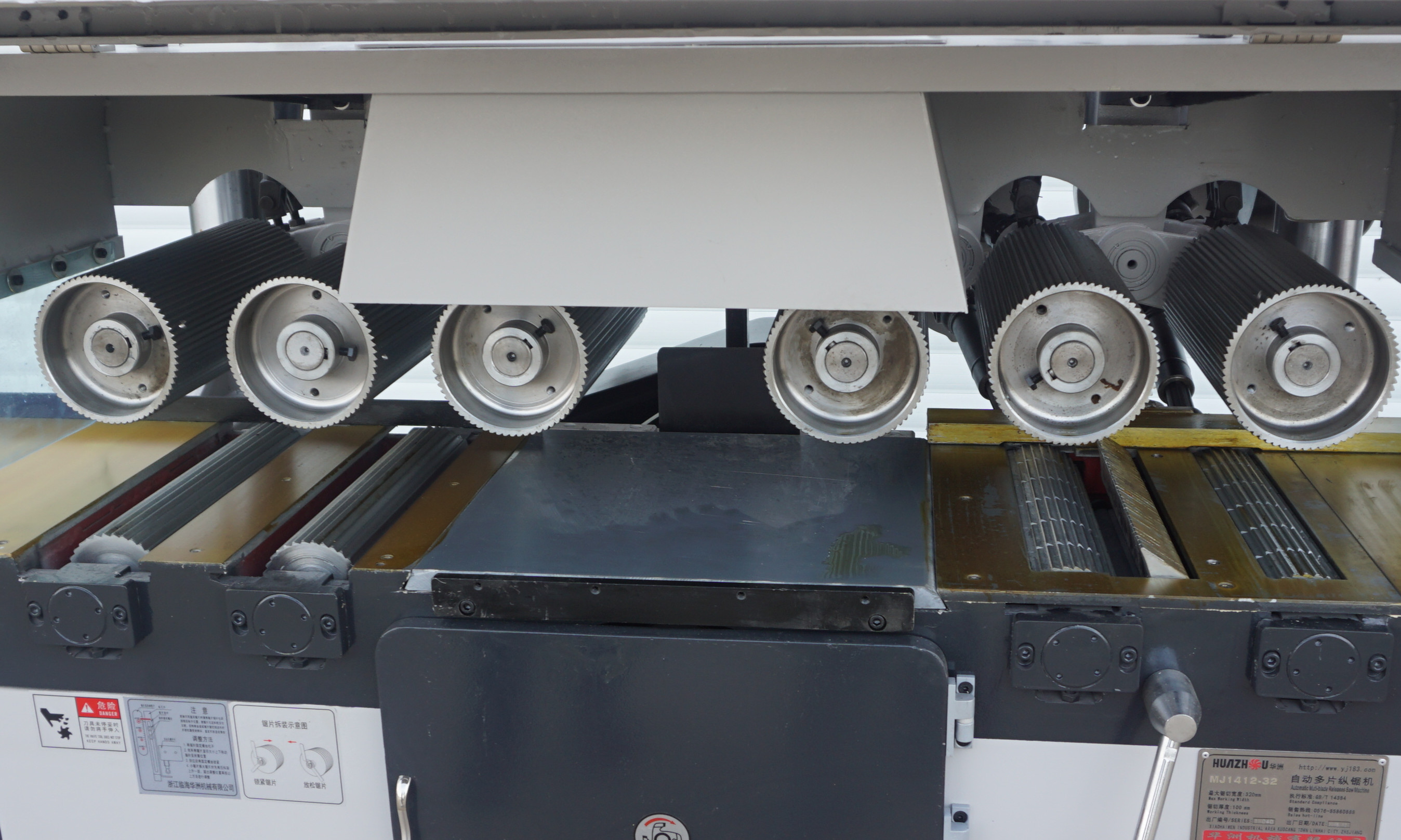

The upper and lower four driving wheels are fed synchronously, which is powerful and powerful.

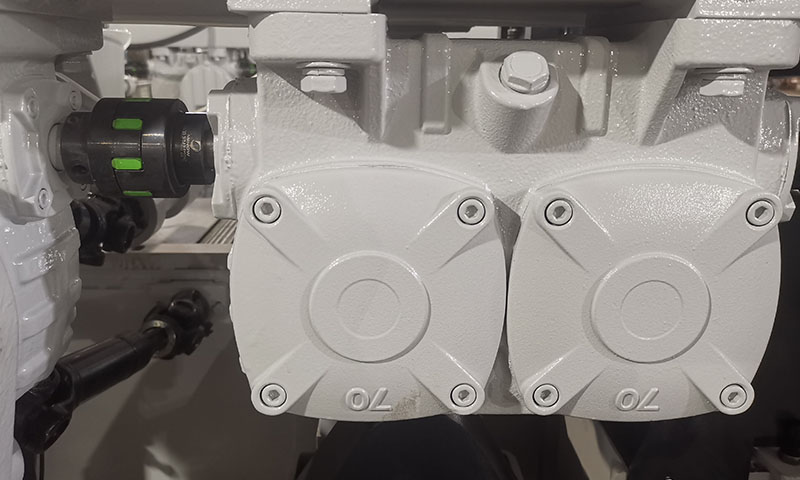

The high-torque reduction worm gear box is equipped with a universal joint for smoother feeding

Up and down multiple anti-rebound devices, effectively prevent the wood from rebounding and hurting people

The feeding speed can be adjusted in multiple gears, and the suitable speed can be selected according to different requirements.

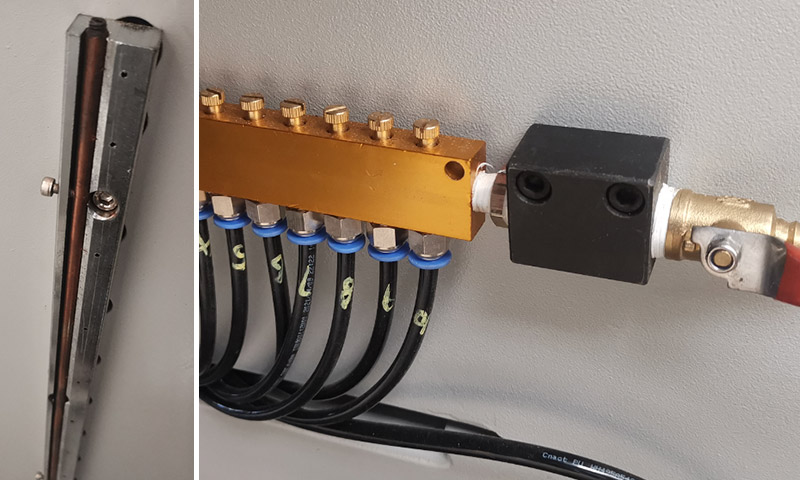

The automatic oil supply pump automatically supplies oil to the key parts of the transmission

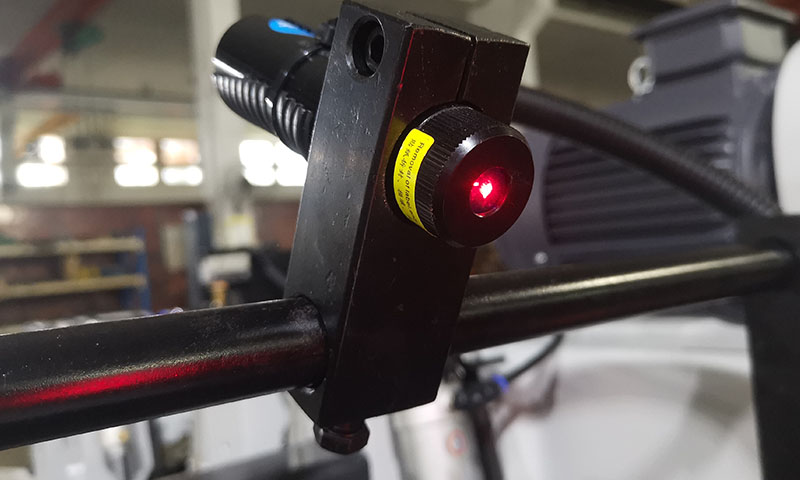

Standard laser marking instrument, accurate alignment of wood sawing position, improve wood yield

Equipped with a spindle sleeve, it is convenient and quick to remove the saw blade

Mist spray device, prolong the service life of the saw blade and reduce the amount of water received by the wood.

Use and Features

1. This machine is specially used for the production of modified materials, wood strips and wood core boards. According to the preset size, multiple wood strips can be sawed out in one feeding. The feeding wheel is used to feed the material, and the upper and lower feeding wheels are used to feed the material synchronously and powerfully.

2. There are 6 groups of upper feeding wheels. The pressure of pressing the wood is controlled by the pressing cylinder, which can be adjusted freely depending on the hardness of the wood.

3. The feeding speed adopts stepless speed regulation, which is easy to adjust and maintain.

4. Feeding wheel feeding is more economical and safer than crawler feeding, and it is easier to control and maintain. The pressing material uses air pressure, so even if the thickness of the wood changes greatly, the pressing material pressure is also fixed, and the thickness of the pressing material is wide, up to 35 mm.

5. Electric adjustment of the upper feeding wheel frame and the lifting and lowering of the saw blade spindle is easy to operate.

6. The saw blade spindle can be lowered to make the saw blade leave the saw blade work surface, and it is easy to replace the saw blade.

7. The main shaft is made of special alloy steel, which has undergone multiple heat treatments and precision grinding.

8. The main shaft adopts large-scale high-precision bearings, which are load-resistant and have a long service life.

9. There are upper and lower safety film groups and side safety baffles to protect the safety of operators.

use video

technical parameter

Recommended Products

Address: Xiaohaimen Industrial Zone, Kuocang Town, Linhai City, Zhejiang Province

Sales Hotline: 86-576-85860183 4001-660183

Mobile phone: 15888672555

Customer Service: 86-576-85860888

Fax: 86-576-85860088

Mailbox: webmaster@yj183.com

Website: www.yj183.com

Website: en.zjhuazhou.cn

Follow us

Follow us

Copyright © 2020 Linhai Huazhou Machinery Co., Ltd. All rights reserved 浙ICP备13032899号-2 Website building:300.cn

QR code

QR code