details and description

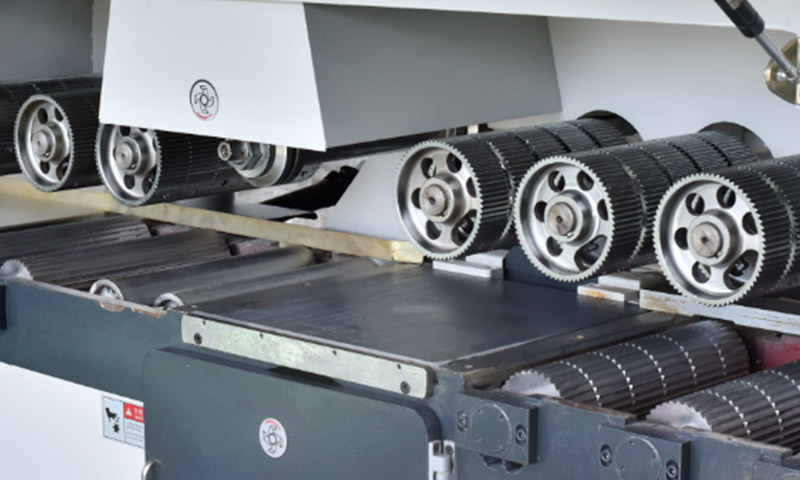

The upper and lower six driving wheels are synchronously feeding, which is powerful and powerful

The automatic oil supply pump automatically supplies oil to the key parts of the transmission

Anti-rebound device, effectively prevent wood rebound from hurting people

The feeding frequency is adjustable, the pressing and the spindle lift are electrically adjusted

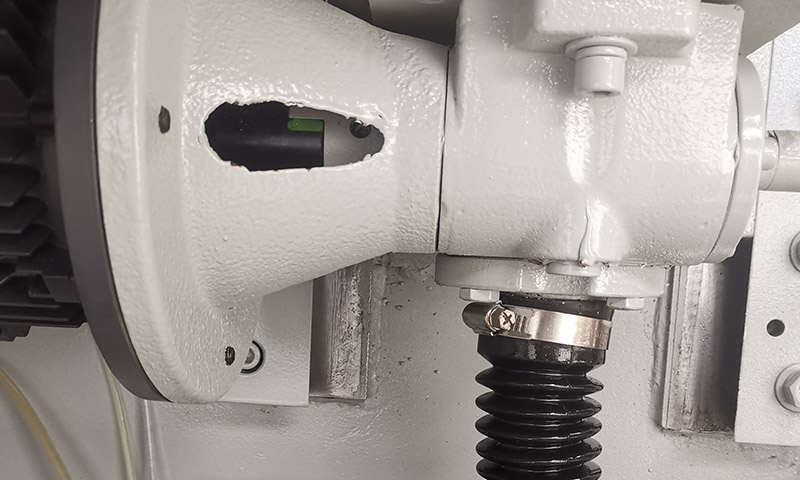

The upper and lower spindles can be raised and lowered independently, suitable for centering sawing of wood of different thicknesses

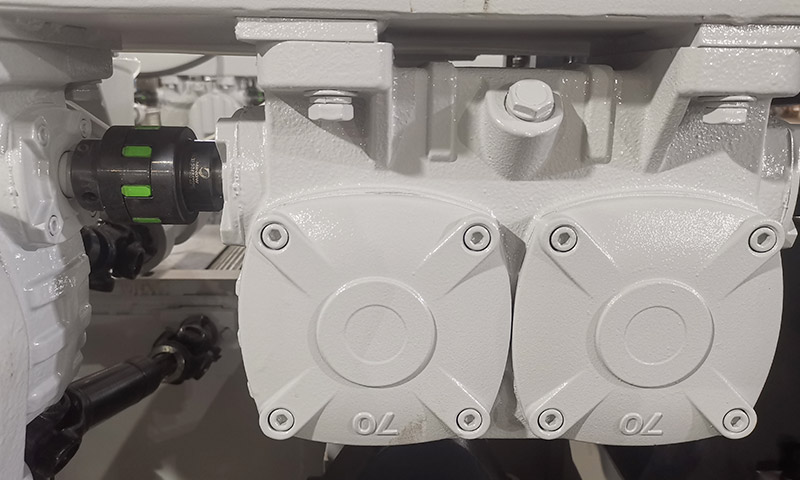

The high-torque reduction worm gear box is equipped with a universal joint for smoother feeding

Optional automatic feeding rack to save labor

Use and Features

1. This machine is specially used for the production of modified materials, wood strips and wood core boards. According to the pre-adjusted size, multiple wood strips can be sawed in one feeding. The feeding wheel is used to feed the material, and the upper and lower feeding wheels are used to feed the material synchronously and powerfully.

2. There are 7 sets of upper feeding power wheels and 7 sets of lower feeding wheels. The feeding is strong and powerful. The pressure of pressing the wood is controlled by the pressing cylinder, which can be adjusted freely depending on the hardness of the wood.

3. The feeding speed is controlled by frequency conversion, which is convenient to adjust the speed, and the speed figures are displayed intuitively.

4. The feeding wheel type feeding is easy to control and maintain, and the pressing material uses the air pressure type. Even if the thickness of the wood changes greatly, the pressing pressure is also fixed.

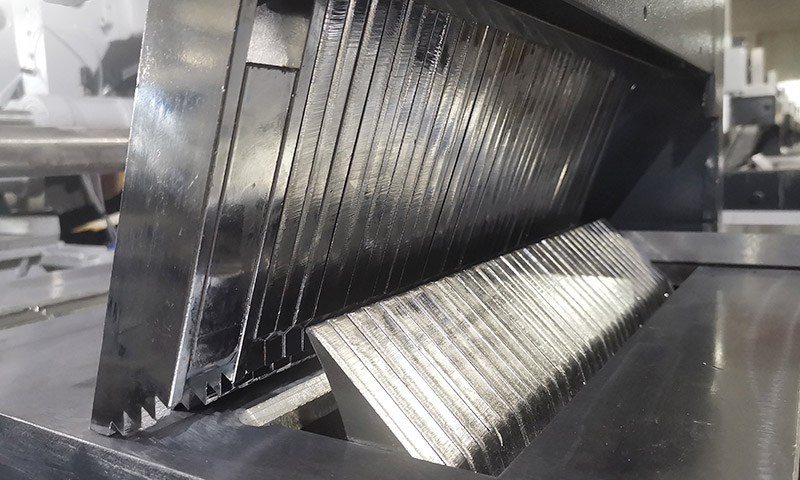

5. There are two layers of upper claws and one layer of lower claws, a total of three layers of detent devices to fully protect the safety of the operator.

6. The diameter of the main shaft is 60 mm, which is made of special alloy steel, and has undergone multiple heat treatments and precision grinding.

7. The spindle bearings are all large-sized and high-precision bearings, which are load-resistant and have a long service life.

8. The saw blade adopts an internal cooling device to mechanically cool the saw blade, which prolongs the service life of the saw blade and reduces the cost of purchasing the saw blade.

9. The coolant supply is synchronized with the spindle operation, the spindle runs with water, and the water is cut off when the spindle stops.

10. The use of upper and lower sets of saw blades for simultaneous sawing can install smaller and thinner saw blades, which greatly reduces the loss of wood and saves the cost of purchasing saw blades.

11. The column seat, roller seat pin, saw shaft barrel, chain and other parts are equipped with oil supply pump to supply oil, which saves the trouble of oil supply with oil gun; and the roller seat pin is installed with oil bearing, which greatly reduces oil supply Frequency (saving oil supply time and lubricating oil).

12. The upper saw shaft can be adjusted up and down through the dovetail guide rail to facilitate the installation of saw blades with different outer diameters.

use video

technical parameter

Recommended Products

Address: Xiaohaimen Industrial Zone, Kuocang Town, Linhai City, Zhejiang Province

Sales Hotline: 86-576-85860183 4001-660183

Mobile phone: 15888672555

Customer Service: 86-576-85860888

Fax: 86-576-85860088

Mailbox: webmaster@yj183.com

Website: www.yj183.com

Website: en.zjhuazhou.cn

Follow us

Follow us

Copyright © 2020 Linhai Huazhou Machinery Co., Ltd. All rights reserved 浙ICP备13032899号-2 Website building:300.cn

QR code

QR code