details and description

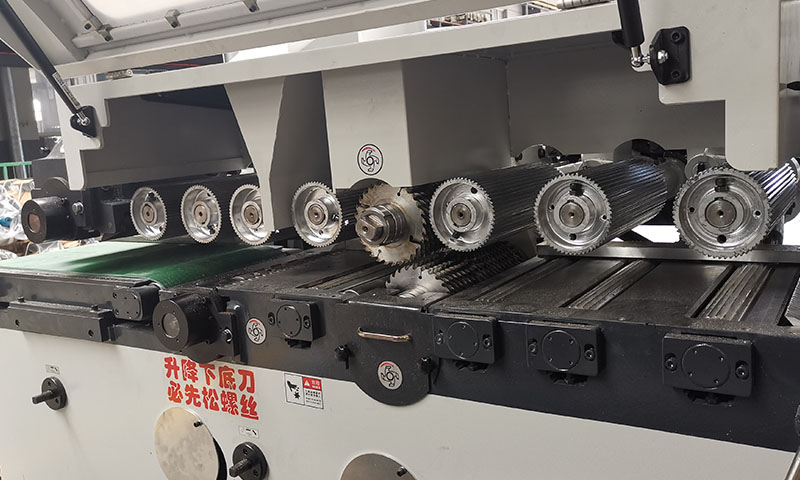

1. Multiple sets of active upper and lower power wheels, feeding more smoothly

2. Upper and lower sets of saw blades for sawing to improve the yield

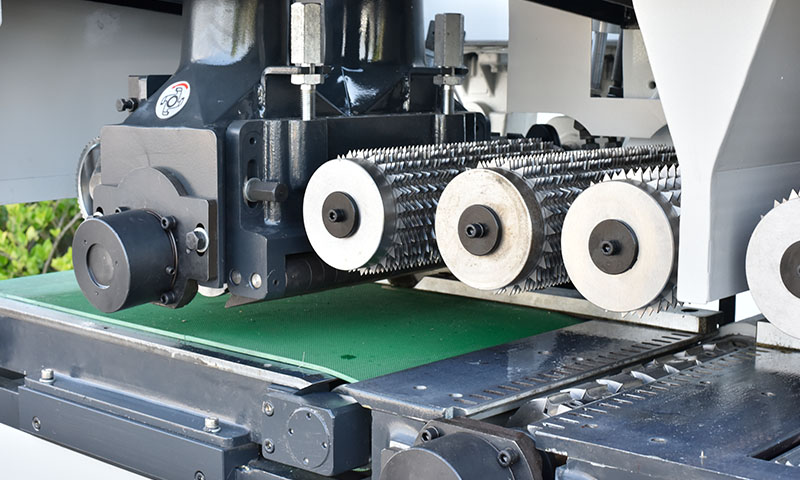

1. Toothed flake wheel, more suitable for short material processing

2. Conveyor belt is adopted for discharging, which is more suitable for short material processing

3. The upper knife planer is equipped with a front external support, which is more suitable for the planing of wide materials

Flake wheel scraper to reduce wood build-up

Equipped with a spiral knife to improve planing accuracy and easy to use

The automatic oil supply pump automatically supplies oil to the key parts of the transmission

The feeding frequency conversion is adjustable, and the pressing material is electrically lifted and lowered, which is intuitive and fast.

Use and Features

1. This machine combines upper and lower multi-blade saws and double-sided planing into one. According to the preset size, multiple wood strips can be sawed and double-sided planed at the same time, which reduces the wood loss rate and improves the efficiency.

2. There are 8 sets of upper feeding wheels. The pressure of pressing the wood is controlled by the pressing cylinder, which can be adjusted freely depending on the hardness of the wood.

3. The feeding speed adopts frequency conversion speed regulation, and the feeding speed can be seen intuitively, which is more convenient to control the speed.

4. Feeding wheel feeding is more economical and safer than crawler feeding, with better control and maintenance. The pressing material adopts air pressure type, so even if the thickness of the wood changes greatly, the pressing material pressure is also fixed, and the thickness of the pressing material is wide, up to 35 mm.

5. Electric adjustment of the upper feeding wheel frame, easy operation.

6. The rear discharge table is discharged with a conveyor belt, which makes the feeding smoother and more convenient.

7. The main shaft is made of special alloy steel, which has undergone multiple heat treatments and precision grinding.

8. The main shaft adopts large-scale high-precision bearings, which are load-resistant and have long service life.

9. Up and down the safety film group to protect the safety of the operator.

10. This machine has the function of automatic deceleration of the saw blade is not sharp, and there is an indicator light to warn you.

11. This product is only suitable for the processing of standard wood, not suitable for the processing of wood with edges on both sides

use video

technical parameter

Recommended Products

Address: Xiaohaimen Industrial Zone, Kuocang Town, Linhai City, Zhejiang Province

Sales Hotline: 86-576-85860183 4001-660183

Mobile phone: 15888672555

Customer Service: 86-576-85860888

Fax: 86-576-85860088

Mailbox: webmaster@yj183.com

Website: www.yj183.com

Website: en.zjhuazhou.cn

Follow us

Follow us

Copyright © 2020 Linhai Huazhou Machinery Co., Ltd. All rights reserved 浙ICP备13032899号-2 Website building:300.cn

QR code

QR code