details and description

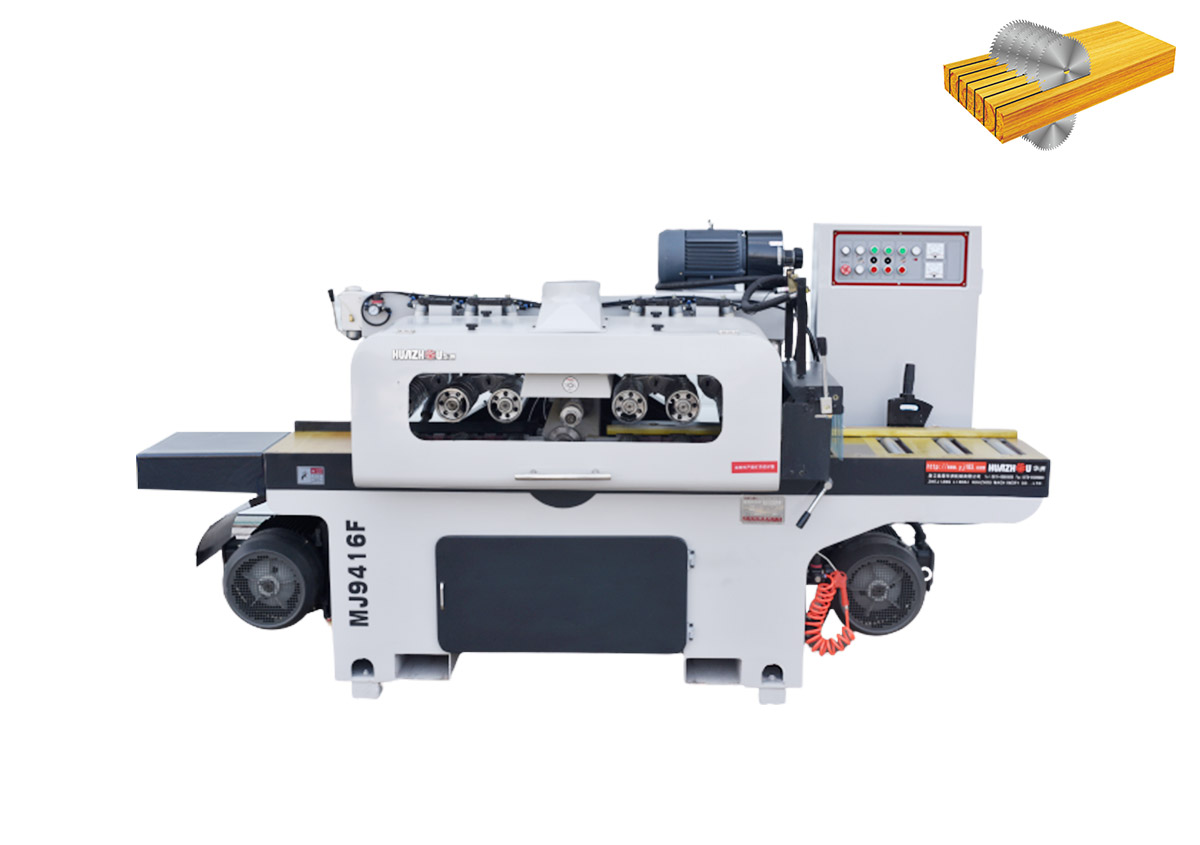

1. Synchronous feeding of upper and lower six driving wheels, strong and powerful

2. The lower feeding wheel is equipped with front support, which is more suitable for wide material processing

The feeding frequency conversion is adjustable, and the pressing material lifting and lowering is adjusted electrically.

The upper and lower spindles can be raised and lowered synchronously, suitable for centering sawing of wood of different thicknesses

The front guide plate can be adjusted in position according to the wood specifications to improve the yield

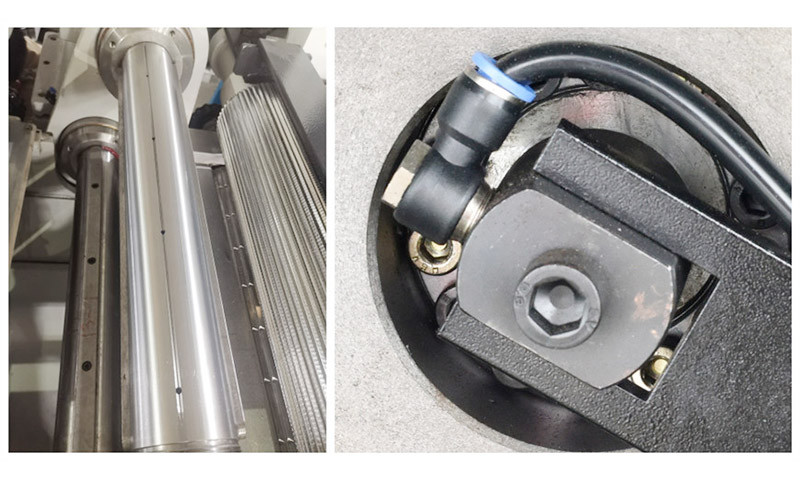

The water spray device in the shaft prolongs the service life of the saw blade and minimizes the amount of water received by the wood.

The water spray device in the shaft prolongs the service life of the saw blade and minimizes the amount of water received by the wood.

Purpose and characteristics

1. This machine is specially used for the production of modified materials, wood strips and wood core boards. According to the preset size, multiple wood strips can be sawed out in one feeding. The feeding wheel is used to feed the material, and the upper and lower feeding wheels are used for synchronous feeding.

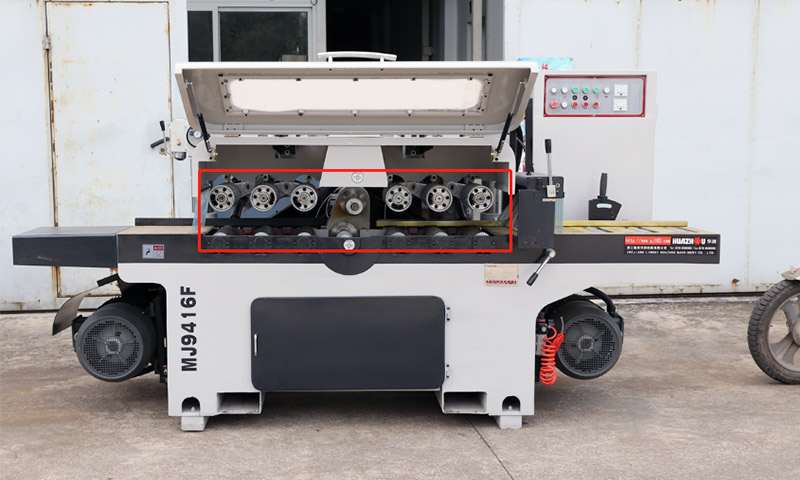

2. There are 6 sets of upper feeding power wheels and 6 sets of lower feeding wheels. The feeding is strong and powerful. The pressure of pressing the wood is controlled by the pressing cylinder, which can be adjusted freely depending on the hardness of the wood.

3. The feeding speed can be changed steplessly, and can be adjusted elastically according to the nature of the wood.

4. The feeding wheel type is good for control and maintenance, and the pressing material adopts the air pressure type. Even if the thickness of the wood changes greatly, the pressing pressure is also fixed.

5. The pressure cylinder can adjust the height of the upper feeding wheel according to the thickness of the wood, which is easy to operate.

6. The diameter of the main shaft is 50 mm, using special alloy steel material, which has been heat treated and ground for many times.

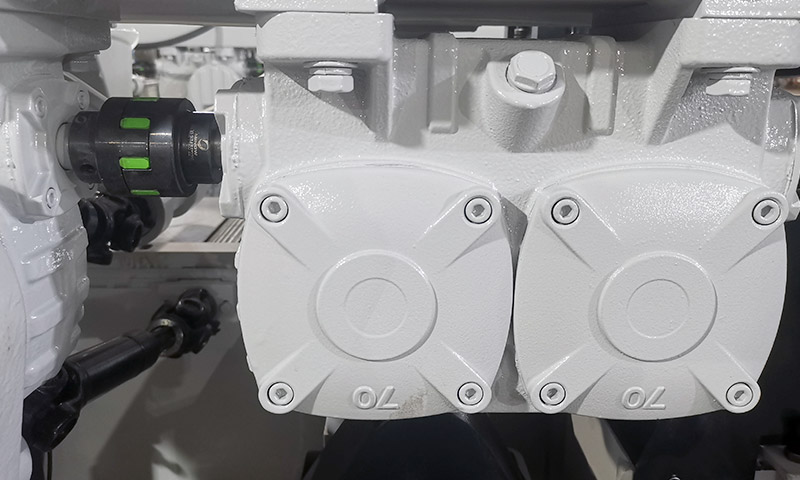

7. The main shaft bearings are all large and high-profile bearings, which are load-resistant and have long service life.

8. The saw blade adopts the patented internal cooling device to cool the saw blade, which prolongs the service life of the saw blade and reduces the cost of purchasing the saw blade.

9. The upper and lower sets of saw blades can be used for simultaneous sawing, and smaller and thinner saw blades can be installed, which greatly reduces the loss of wood and saves the cost of purchasing saw blades.

10. The column seat, roller seat pin, saw shaft barrel, chain and other parts are equipped with oil supply pump to supply oil, which saves the trouble of oil supply with oil gun; and the roller seat pin is installed with oil bearing, which greatly reduces oil supply Frequency (saving oil supply time and lubricating oil).

11. The saw shaft seat is installed on the dovetail guide rail mechanism, which can be raised and lowered synchronously, so that the upper and lower saw blades can be centered and cut, so that the upper and lower groups of saw blades can be balanced in force.

use video

technical parameter

Recommended Products

Address: Xiaohaimen Industrial Zone, Kuocang Town, Linhai City, Zhejiang Province

Sales Hotline: 86-576-85860183 4001-660183

Mobile phone: 15888672555

Customer Service: 86-576-85860888

Fax: 86-576-85860088

Mailbox: webmaster@yj183.com

Website: www.yj183.com

Website: en.zjhuazhou.cn

Follow us

Follow us

Copyright © 2020 Linhai Huazhou Machinery Co., Ltd. All rights reserved 浙ICP备13032899号-2 Website building:300.cn

QR code

QR code